Add to Cart

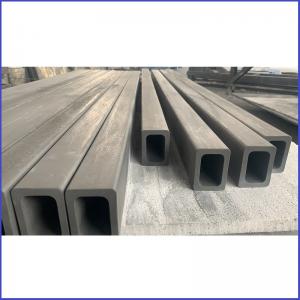

high temperature resistance sisic ceramics beam for bearing structure used to tunnel kiln

Properties of Silicon Carbide (SSiC / SiSiC) Beam

Low density (3.07 to 3.15 g/cm3)

High hardness (HV10 ≥ 22 GPa)

High Young’s modulus (380 to 430 MPa)

High thermal conductivity (120 to 200 W/mK)

Low coefficient of linear expansion

(3.6 to 4.1x10-6/K at 20 to 400°C)

Maximum operating temperature of SSiC under inert gas: 1,800°C

Excellent thermal shock resistance of SiSiC: ΔT 1,100 K

Erodible

Corrosion and wear resistant even at high temperatures

Toxicologically safe

Good gliding properties

Products made from Silicon Carbide (SiSiC/SSiC) Beam

Advanced Ceramic Tubes

Bearing Technology in Automotive Engineering

Mechanical Engineering Special Applications

Pumps, Components for

Regulator Discs

ROCAR®

Seal and Regulator Discs

Seal Rings, Bearings and Sealing

Tubes and Pipe

| Silicon Carbide Product Specification: | ||||

| Item | Unit | SSIC | RBSIC SISIC | R-SIC |

| Purity | ( % ) | ≥ 99 | ≥90% | ≥ 99 |

| Application temperature | ºC | 1700 | 1380 | 1650 |

| Density | g/CM2 | ≥3.10-3.15 | ≥3.02 | 2.65-2.75 |

| Open porosity | % | ≤0.1 | ≤0.1 | |

| Hardness | ≥92 HRA | 2400 Kg/mm2 | 1800-2000 Kg/mm2 | |

| Bending strength | MPa | 400-580 | 250(20ºC) | ≥300 |

| 281(1200ºC) | ||||

| Tensile strength | Mpa | ≥200 | ≥190 | |

| modulus of elasticity | GPa | 400 | 332(20ºC) | 80-100(20ºC) |

| 300(1200ºC) | 90-110(1200ºC) | |||

| Thermal Conductivity | W/m.k | 100-120 | 45(1200ºC) | 36 |

| Coefficient of thermal expansion | K1X 106 | 4.2 | 4.5 | 4.6 |

| Rigidity | Gpa | >25 | 13 | |

| Acid&Ikali resistance | Excellent | Excellent | Excellent | |

Photos for reference:

What can we do for you?

1. Sample is available.

2. Independent R&D, ISO manufacture, precise quality standards, modern logistics management, and sound marketing strategy.

3. Inquiry replied within 24 hours.

4. Patented products.

5. OEM or ODM is available.

6. Some extra accessories can be supplied.

7.The larger quantity you order,the more competitive prices you'll get.

8. Necessary Certificates can be supplied.

If you have another question, pls feel free to contact us as below:

Yui

WEIFANG BETTER CERAMIC CO., LTD

MOB:+86-18615910108(Whatsapp)

TEI:+86-536-2693828

Wechat:18615910108 QQ:3001737400

Email:yui@wf-better.com Web:www.wf-better.com

Hot tag:ceramics square beam,for tunnel kiln,supplier,factory,manufactures,good price,china wholesaler,building ceramics

Tag:reaction boned silicon carbide cross pipe/tube,refractory,bearing structure beam,kiln furance,industrial procelain